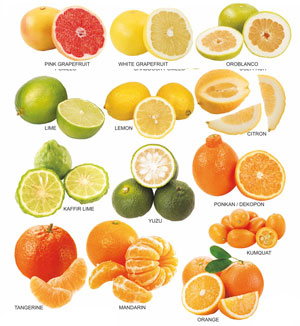

Raw materials of orange juice processing line

Our orange juice processing line is suitable for large-scale industrial production. The most important machine fruit peeling and extracting machine is widely used in oranges, grapefruits, lemons, limes, citrons and tangerines which are some of the most common citrus fruits, bananas, pineapples and other fruits. AGICO orange juice processing line can process all above fruits into juice.

Introduction of orange juice processing Line

Our company supplies complete orange juice processing line which is researched and developed by our technicians according to the advanced technology from German and Italy for many years. Our orange juice processing line integrates the functions of peeling and juicing, no need to grade the fruit during production. The processing capacity for orange juice processing line is 3-10 tons per hour. And AGICO supplies different kinds of orange juice processing line according to customers’ requirements.

Main Features of the orange processing line

- With advanced technology from German and Italy.

- High efficiency and large output without classification.

- No needing for two steps processing.

- The parts contacting with raw materials directly are made of stainless steel 304.

- Being suitable for large-scale industrial production.

- The floor area of the workshop is approximately 30m multiply by 5m. And the power consumption is about 105kw.

Procedures of orange juice processing line

The main procedures of citrus fruit juice processing line are sorting the proper fruits→cleaning the oranges→elevating oranges→peeling and squeezing orange→refining orange juice . In accordance with the procedures, the primary machineries are as follows: fruit elevator, fruit sorting machine, brush and spray fruit cleaning machine, surfing type fruit washing machine, orange essential oil extraction machine, fruit peeling and extracting machine, etc. Let’s look at the main procedures and some main machines of orange juice processing line together.

Sorting and washing proper oranges

The first step of building such an orange juice processing line is to choose the most suitable oranges which is the most important pretreatment work. The principle of choosing orange is that the fruit must be of good sensory quality and high nutritive value, high juice yield, fresh and proper maturity and sugar-acid radio. It is necessary and main to use brush and spray fruit cleaning machine and rolling rail fruit sorting machine in this procedure.Fruit sorting machine

Rolling rail fruit sorting machine is necessary and widely used for sorting of citrus fruit by manual. Citrus fruit can rotate freely on the roller by the rotation and revolution designing, the fruit can be more sanitary and of much higher quality after being cleaned and sorted.

Main features of fruit sorting machine:

- With High quality stainless steel roller to transport orange and the speed can be adjustable.

- The rack is made of 1.5mm stainless steel hairline folded plate channel.

- It conforms to the manufacturing standards of food.

- It contains the tray which can receive sundries.

| Power | Dimension | Production capacity |

|---|---|---|

| 1.1kw | 4000*850*1100mm | 5ton/h |

Brush and spray fruit cleaning machine

Brush and spray cleaning machine fits to remove of extraneous matters and eliminate the stickiness contained on most of the citrus peels. Citrus fruits irregularly rotate in every direction continuously, and at the same time brushing and spraying is carried out under the effect of rotary brush roller. Thus at last the dirt can be cleaned completely without breaking the citrus fruit.

Technical parameter of brush and spray fruit cleaning machine

| Power | Dimension | Width of cleaning | Length of cleaning | Power of circulating water pump | Production capacity |

|---|---|---|---|---|---|

| 2.0kw | 2335*1510*1325 mm | 1000mm | 1816mm | 3.0kw | 5ton/h |

Fruit Surfing washing machine

Surfing washing machine, also can be called fruit bubble washing machine, the working principle is the blower runs the air and makes the water keep rolling, rapid flow scours the surface of the raw materials and washes the dirt out without breaking the completeness of raw materials and then lifts the cleaned fruit into the elevator.

Main features of fruit surfing washing machine- With circulating water pump to supply high pressure flowing water to wash fruits.

- Washing water can be recycled after filtering.

- Rinse tank adapts 1.5mm stainless steel and the transmission shaft is made of 1Cr13 stainless steel.

- The height matches the peeling juicer.

| Power | Lifting width | Rinse tank length | Lifting angle | Dimension | Production capacity |

|---|---|---|---|---|---|

| Hoisting plant----2.2kw | 600mm | 2600mm | 35° | 2800*1100*3380mm | 5ton/h |

Fruit peeling and extracting machine

Fruit peeling and extracting machine is the new type of fruit juice equipment combined with international advanced technology. It integrates peeling and juicing with the characteristics of easy operation and high juice yield rate. Fruit peeling and extracting machine is suitable to process many kinds of fruits such as citrus, passion fruit, bananas and pineapple etc.

The advantages of fruit peeling and extracting machine

- The processing capacity is from 3-10 ton.

- It is easy to operate fruit peeling and extracting machine and with high efficient and high juice yield.

- The effect of extrusion can be adjusted according to the different kinds of fruit.

- It is equipped with bucket for receiving juice, pulp transporter and rind transporter.

| Type | Production capacity(t/h) |

Motor power (kw) |

Overall dimension (mm) |

|---|---|---|---|

| TCBZ-1 | 3 | 8 | 1600*1200*1800 |

| TCBZ-2 | 5 | 11 | 1800*1300*2200 |

| TCBZ-3 | 10 | 15 | 2000*1350*2500 |

Orange essential oil extraction machine

According to the market survey, with the improvement of living standards and pursuit of quality of life, by-products of orange became a necessity in our daily life. Orange essential oil is one of the most potential products, on this occasion, orange essential oil extraction machine is becoming more and more popular, and in AGICO orange juice processing line, we offer the line with orange essential oil extraction machine, want to know more about orange essential oil extraction machine, please click here.