Description of CT-C Hot Air Circulating Drying Oven

The CT-C series hot air circulation oven is equipped with a low-noise, high-temperature-resistant axial flow fan and an automatic temperature control system. The entire circulation system is fully enclosed, which improves the thermal efficiency of the oven from 3%-7% of the traditional drying room to the current 45%-50%, the highest thermal efficiency can reach 60%. The successful design of the CT-C series hot-air circulation oven has enabled China's hot-air circulation oven to reach the advanced level at home and abroad, saving a lot of energy for China and improving the economic benefits of the enterprise.

Most of the hot air circulates in the oven, with high thermal efficiency and energy saving. Using the effect of forced ventilation, the oven is equipped with an adjustable air distribution board, so that the materials are dried evenly. The heat source can be steam, hot water, heat-conducting oil, electricity, hot blast stove, of a wide range of choices. The whole machine has low noise and stable operation. Automatic temperature control, easy installation and maintenance.

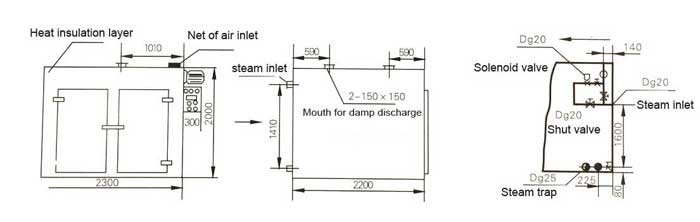

Dimensional diagram of CT-C-Ⅱ drying oven

Application of CT-C Hot Air Circulating Drying Oven

It is suitable for drying a very large variety of fruits and vegetables, such as, mango, blueberry, strawberry, lemon, apple, banana, orange, blackberry, peach, kiwifruit, etc, or ginger, onions, carrots, cucumbers, garlic and so on.

Features of CT-C Hot Air Circulating Drying Oven

- There are six heating methods: water, steam, electricity, heat-conducting oil, electricity and steam mixed, and hot air stove.

- Operating temperature: water and steam heating 50-140℃, the highest is 150℃, hot air stove, heat transfer oil 50~300℃ electric heating 50-650℃.

- The whole machine has good sealing performance, and the unique guide rail sealing device ensures the sealing performance of the whole machine.

- The double-door oven can realize mechanical interlocking.

- All parts in the oven can be quickly disassembled and installed to facilitate cleaning.

- The control system is equipped with text display and touch screen to choose from.

- The company combines foreign experience and domestic "GMP" requirements, carefully design and manufacture.

- Production capacity and energy counting methods: 400-500kg/h.

- Commonly used steam Pressure: 0.2~0.8 Mpa(2-8kg/cm2).

- The special requirements should be indicated at the time of order.

- Please consult as for any special requirements.

- For operation temperature of over 140℃ or less than 60℃, please indicate when order.

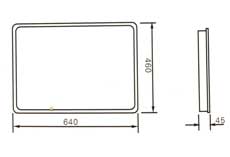

- Baking plate dimensions: 460*640*45mm.

Service Commitment

a.Design and production:

In the design and production period of undertaking equipment processing, our company extensively solicits the opinions of the buyer, especially considers the buyer's site conditions and public engineering conditions, so that the equipment can ensure the most optimized combination.

b.Installation and debugging:

When the equipment arrives in the buyer's factory, our company can send a full-time technician to the buyer to guide the installation and be responsible for debugging to normal use. The buyer provides board and lodging and round-trip air tickets.Under recent COVID conditions, we can supply free remote video guidance.

c. Training:

Before the buyer uses the equipment normally, the commissioning personnel of our company will train relevant personnel of the buyer to conduct. The training content includes: equipment maintenance, maintenance, timely repair of common faults, and equipment operating procedures.

d.Quality Assurance:

The warranty period of our company's equipment is one year. During the warranty period, the equipment is damaged by non-human factors, and it is responsible for free maintenance. If the equipment is damaged by human factors, our company will repair it in time and charge a cost fee.

e.Maintenance and deadline:

Our company provides high-quality, competitive-priced parts and accessories to the buyer for many years, and provides related supporting life-long services. They are once shaped. The materials are stainless steel, rustproof aluminum alloy and A3 steel.

.jpg)

Basic principles of plant design

- The ground should be paved with non-permeable, non-absorbent, non-toxic, non-slip materials, and the ground should be seamless and easy to clean and disinfect. The ground should have an appropriate slope (1.0%-1.5% is appropriate) and have a good drainage system. The drainage ditch is an arc-shaped open ditch. If it is drained in a dark ditch, rodent nets must be set up. The ground is solid, the thickness of the concrete layer is not less than 50mm, and the ground should be covered with tiles or terrazzo or painted with environmental resin.

- The wall should be paved or coated with light-colored, mildew-proof, anti-permeable, non-toxic materials, and the surface should be smooth and easy to wash and disinfect. The top corners, wall corners, and ground corners are arc-shaped to prevent dirt from accumulating and facilitate cleaning.

- The ceiling should be coated or decorated with light-colored materials that do not absorb water, have a smooth surface, anti-mold, and anti-leakage. It should have an appropriate slope to reduce condensation and dripping on the structure.

- Doors and windows should be tight and made of non-deformable and corrosion-resistant materials. If there is an inner window sill, it should be inclined down 45°. Doors and windows must be equipped with effective facilities for preventing mosquitoes, flies and insects. The door should be able to close automatically and tightly.

- Ventilation equipment: the workshop must be equipped with ventilation equipment. The air flow direction should avoid flowing from the unclean area to the clean area. The vent must be equipped with a corrosion-resistant protective cover that is easy to clean and replace, and the air inlet must be at least 2m above the ground and far away from pollution sources and exhaust vents.

- Daylighting and lighting: The workshop or working surface should have sufficient natural or artificial lighting. The lighting coefficient of the workshop should not be lower than the standard IV level; the mixed illuminance of the working surface of the inspection site should not be less than 540lx; the illuminance of the working surface of the processing site should not be less than 220lx; other places should not be less than 110lx. The lamps installed above the production line in the workshop must have safety protection devices to prevent the lamps from being broken and contaminating food.

- Fire-fighting requirements: The process system does not require special fire-fighting facilities, and the fire-fighting of the factory building is set by the construction unit in accordance with the law.

- All equipment does not require anchor bolts, protective barriers and enclosures.

Technical parameters

| Spec. of industry standard | Specification | Batch drying capacity(kg) | Power(kW) | Steam to be consumed(kg/h) | Heat exchange area(㎡) | Velocity(m3) | Temperature different of the top and the bottom(℃) | Baking trays | Overall dimensions (LxWxH)mm | Baking cart to be used (set) |

|---|---|---|---|---|---|---|---|---|---|---|

| RXH-5-C | CT-C-O | 25 | 5 | 5 | 5 | 3400 | ±2 | 8 | 1400x1200x1600 | 0 |

| RXH-14-C | CT-C-ⅠA | 50 | 0.45 | 10 | 10 | 3400 | ±2 | 24 | 1400x1200x2000 | 1 |

| RXH-14-C | CT-C-Ⅰ | 100 | 0.45 | 18 | 20 | 3450 | ±2 | 48 | 2300x1200x2000 | 2 |

| RXH-27-C | CT-C-Ⅱ | 200 | 0.9 | 36 | 40 | 6900 | ±2 | 96 | 2300x2200x2000 | 4 |

| RXH-41-C | CT-C-Ⅲ | 300 | 1.35 | 54 | 80 | 10350 | ±2 | 144 | 2300x3220x2000 | 6 |

| RXH-54-C | CT-C-Ⅳ | 400 | 1.8 | 72 | 100 | 13800 | ±2 | 192 | 4450x2200x2000 | 8 |

| RHX-25-A | High effect and high temperature far infrared sterilization oven. The power will be equipped in accordance with the requirements of temperature. | 1200x1000x1600 | ||||||||